Punch&Press

2023-10-31

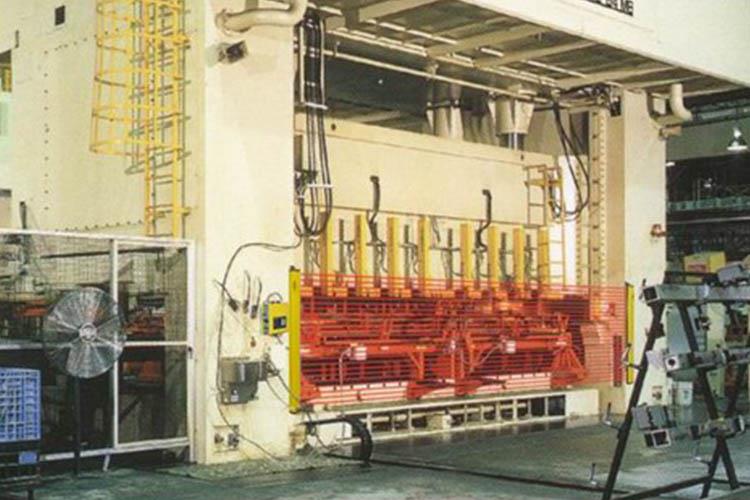

The photoelectric protection device is economical and efficient, maximizing the protection of the operator's personal safety.

1. Working principle:

The photoelectric protection device of the punching machine consists of five parts: a light emitter, a light receiver, a controller, a signal cable, and a control cable (supporting PNP and NPN outputs).

The light emitted by the illuminator is directed towards the receiver, forming a protective light curtain. When the light curtain is obstructed, the light receiver generates a light blocking signal, which is transmitted to the controller through a signal cable. The controller processes this signal to generate a control signal, which controls the braking control circuit of the machine tool or other equipment alarm devices to achieve machine tool parking or safety alarm.

2. Selection instructions:

STF series photoelectric protection device

Optical wheelbase: 40mm

Protection height: (number of optical axes -1) * optical axis distance

Suitable for machine tools (machine table tops) or protection areas with a length of less than 0.4-3 meters.

SNA series photoelectric protection device

Optical wheelbase: 20mm, 30mm, 40mm, 80mm

Protection height: (number of optical axes -1) * optical axis distance

Suitable for protecting machine tools (machine table tops) or protected areas with a length of less than 3 meters.

SNB and SNC series photoelectric protectors

Optical wheelbase: 20mm, 30mm, 40mm, 80mm

Protection height: (number of optical axes -1) * optical axis distance

Suitable for protecting machine tools (machine table tops) or protected areas with a length of less than 8 meters.

STD series photoelectric protector

Optical wheelbase: 10mm, 20mm, 40mm

Protection height: (number of optical axes -1) * optical axis distance

Suitable for machine tools (machine table tops) or protection areas with a protection length of 0-15 meters or less.

The protection height should not be less than: machine tool slider stroke+adjustment amount